IBC MIXERS

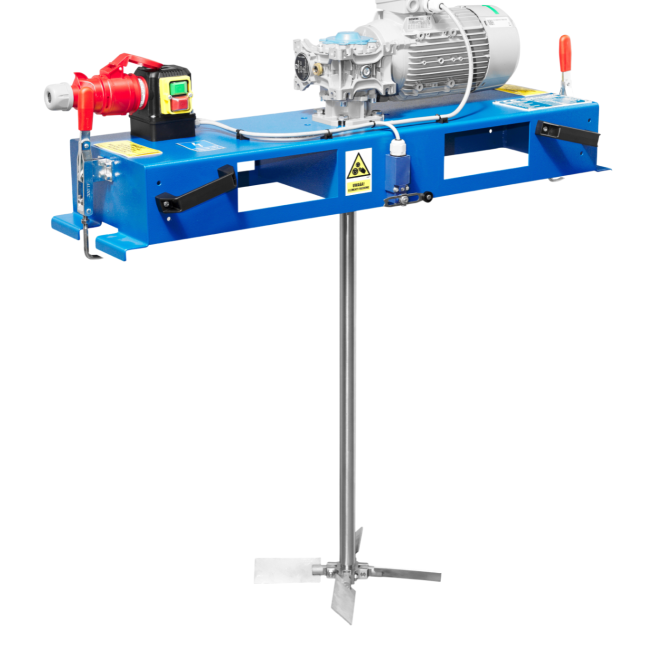

Portable mixers for 1000 L IBC containers. We offer mixers with electric or pneumatic motors for liquids with a viscosity of up to 10,000 mPas. Each device is equipped with an emergency circuit breaker and a limit switch.

ADVANTAGES

- The mixer stirrer is made of 316 Ti steel approved for contact with food.

- It has pockets for handling with a forklift.

- The versions with electric or pneumatic drive are available.

- The mixers with electric motor can be equipped with smooth speed control by inverter.

USE

- The mixers are designed for 1000 litres containers with DN 150 opening or bigger.

- Used for mixing, homogenizing and dissolving.

- ATEX explosion-proof version for zone 1 (option).

MIXER DRIVE

An angular (worm) gear with an electric motor is used as a standard. The motor parameters, i.e. torque, power supply and rpm are selected individually, depending on the type of fluids used.

BODY (TRAVERSE)

It is made of St3 steel, powder coated. A stainless steel version is possible. The body of the mixer is equipped with handles which enable manual pulling the mixer out of the tank. The mixer also has special handles to allow the use of a forklift for pulling out. It is also possible to make a handle for hanging the mixer on the winch.

ELECTRIC CONTROL

Allows the device to work safely. In accordance with the applicable standards. At the customer's request, a mixer can be made with smooth speed control using an an inverter.

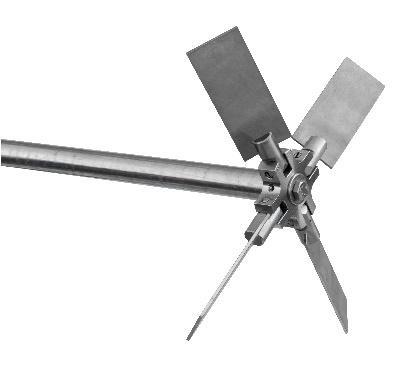

FOLDING MIXER

Adapted to openings in tank. Minimum size of opening is DN 150. The mixer blades automatically unfold under the centrifugal force and the liquid resistance. The mixer stirrer is made of acid-resistant steel.

Table of mixers (full offer on mieszamy.pl)

| Drive | ELECTRIC | PNEUMATIC | |||

| Type | MKE-500 | MKE-2000 | MKE-5000 | MKE-10000 | MKP-5000 |

| Maximum viscosity [mPa*s] | 500 | 2,000 | 5,000 | 10,000 | 5000 |

| Motor power [kW] | 0.75 | 0.75 | 1.1 | 1.5 | 1.1 |

| Power supply | 230/400 | 230/400 | 400 | 400 | 6 bar |

| Rotary speed [rpm] | 600/900/1400 | 140/200/280 | 140/200/280 | 140/200/280 | 100 - 300 |

| ATEX | NONE | NONE | NONE | OPTION | OPTION |

| Smooth speed control | OPTION | OPTION | OPTION | OPTION | STANDARD |

| Stainless steel body | OPTION | OPTION | OPTION | OPTION | OPTION |

| Approval for contact with food | STANDARD | OPTION | OPTION | OPTION | OPTION |

| Charging hopper (LIQUID/POWDER) | OPTION | OPTION | OPTION | OPTION | OPTION |

In order to meet the constantly developing technology, we have introduced to our mixers, as an additional option, the possibility of full control by means of mobile devices.

e - Mixer

Primary features:

- Set-up of time for enabling and disabling the mixer;

- Set-up of mixing sequence, e.g. 10 min. Enabled / 1 hour disabled;

- Remote set-up of mixing parameters, including enabling and disabling the mixer

- via on-site LAN (access from PCs located in office rooms);

- Integration of this mixer with visualization and control master systems (SCADA);

- Set-up of mixing parameters using a smartphone via the integrated web server or an additional application;

- An integrated minicomputer allows to implement the features of a standard PC (e.g. installation of office applications, web browser, etc.).

Additional features:

- Collecting, visualizing and archiving process data (mixer rotary speed, enabling time, optionally medium temperature, 78 etc.)

- Expanding the mixer with additional input (e.g. temperature sensor) and output devices (e.g. valves for feed and discharge the medium to be mixed);

- Logging into settings reserved for maintenance services, process engineer, team leader;

- A wide range of features to adapt the functions of the mixer to the customer's needs;

- Detailed range of functions to be determined when ordering