Station of inspection and packing of starters

The machine is used to control the presence and correctness of through bores and threaded holes in starter bases.

The test is carried out using mobile activators and Keyence color sensors. The machine is integrated with an automatically operating detail feeder.

|

Purpose of the machineControl of the correctness of the starter base and the ability to scan product labels.

Description of the operation:

|

Machine tool structure

OPERATOR PANEL

The control elements and the display allow you to view the status of the process and control the individual drives of the machine.

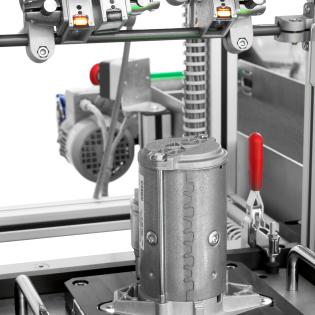

COLOR SENSOR SET

The main tool for checking the correctness of the openings in the starters is a set of five Keyence LR-W500C color sensors. These sensors are pointed at the specific places in the starters and are able to recognize the presence of through bores and the threads in these places.

CONTACT PINS

In the working section of the station, three pressure mechanisms are additionally placed, which, like sensors, are pointed at the key places of the starter. They check the correct insertion of the starter in the socket, which is possible only in the case of the correct shape of the starter base and the correct execution of the through bores.

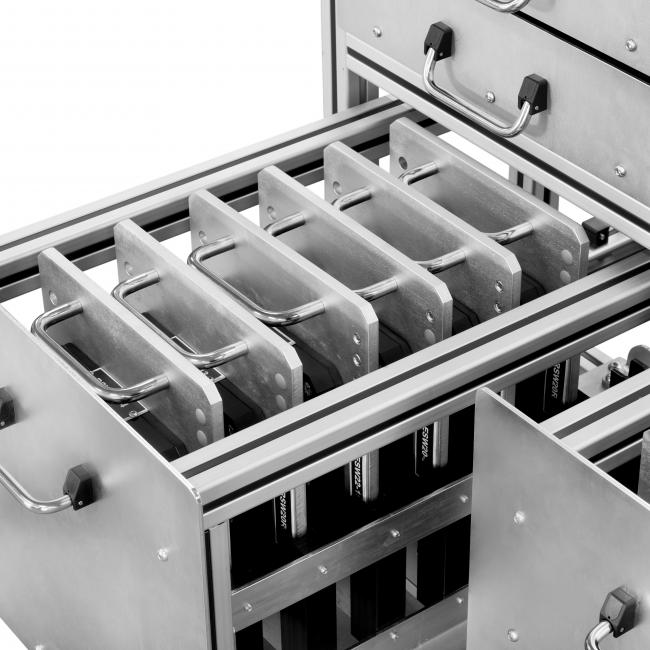

REPLACEABLE SOCKETS FOR STARTERS

The station enables the control of various starters. For this purpose, the system is equipped with sockets dedicated to different references. The bases of starters are stored under the machine in two drawers, 8 pieces in each.

BELT CONVEYOR

The system is additionally equipped with a belt conveyor, which transports starters to the control station. Starters are protected against damage and falling.

SAFETY ASSURANCE LEVEL

In accordance with the customer's guidelines and adaptation to the recommendations of the PN-EN ISO 12100 standard, the system is equipped with a number of technical safety measures, such as: emergency switch, guards.

Benefits for the customer / user

- precise control of starter bases considering their geometry and correctness of through bores;

- quick socket retrofit system (coded). Storage of unused bases in drawers under the machine;

- facilitating the transport of starters to the test station using a belt conveyor;

- increasing production efficiency;

- service access for maintenance workers;

- ergonomic design.