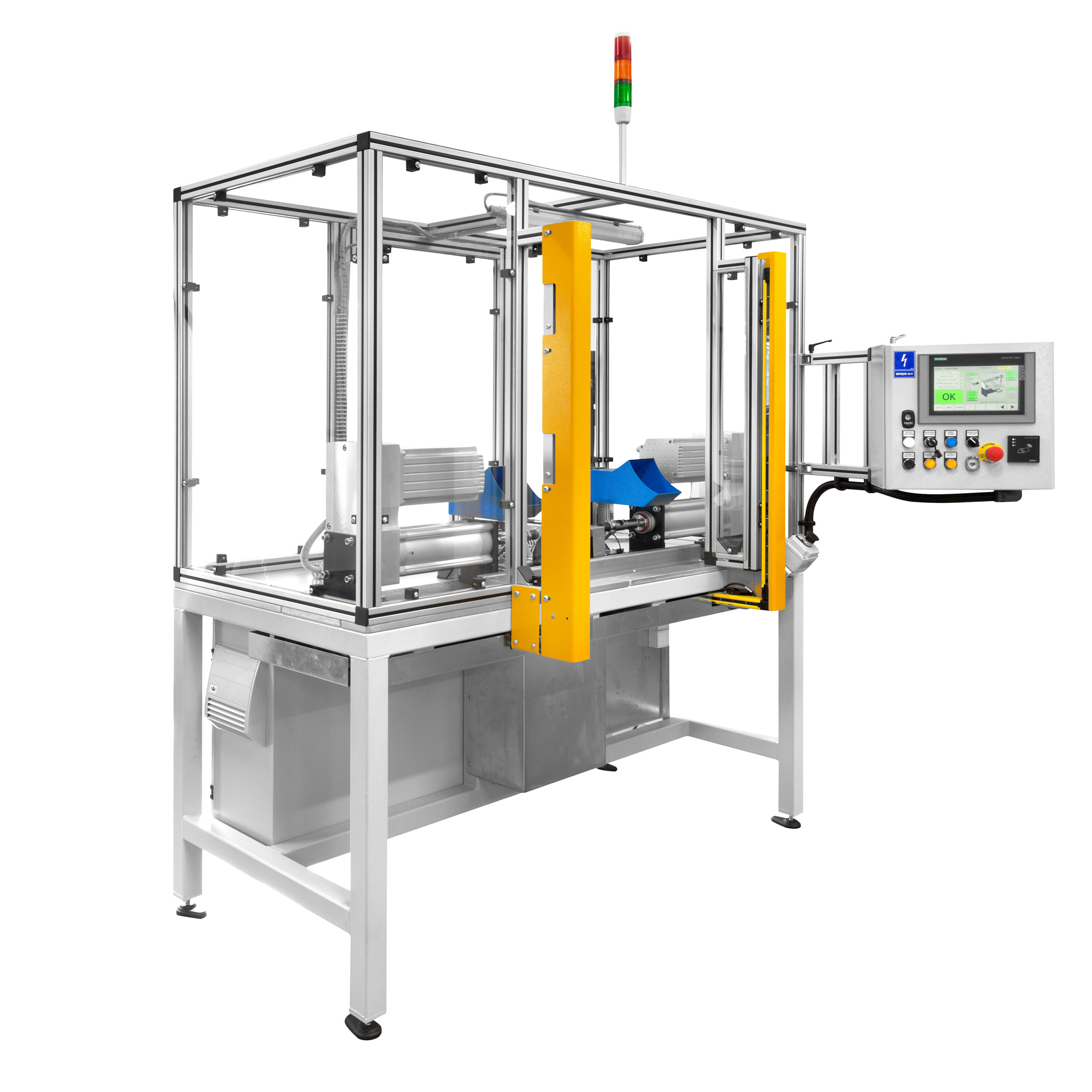

VW336 armrest clamping station

Starlock type ring clamping station with the use of two servo presses and with control of the bending force of the armrest.

Purpose of the machine

The main purpose of the machine is to clamp the Starlock rings in order to obtain the desired bending force for the arm of the armrest.

Description of the operation:

- placing the pre-assembled detail in the socket;

- activating of the automatic cycle with the START CYKLU button;

- fixing of the detail;

- starting of the clamping process with simultaneous measurement of the bending force of the cover;

- ending of the clamping process after reaching the set bending force;

- returning the presses to the basic position and lowering the lifting arm of the cover;

- unblocking of the detail;

- removing the finished detail from the machine.

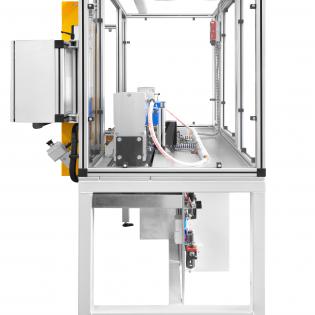

Machine tool structure

OPERATOR PANEL

The control elements and the display allow you to view the status of the process and control the individual drives of the machine.

STARLOCK CLAMPING MODULE

The module, which is based on two Festo C1152501 servo presses, enables precise fixing of the Starlock clamping ring onto the workpiece mandrel. These devices have a stroke of 100 mm and are able to generate a force of up to 17 kN. Simultaneously with the moving of the presses, the bending force of the armrest arm is measured with a strain gauge. When the expected value is reached, the operation of the presses is immediately stopped. This solution means that each detail is treated individually and guarantees the best results.

ARM REST COVER BENDING MODULE

Module works together with clamping presses and it is equipped with a strain gauge. It measures the force required to bend the arm on the base, for which the degree of clamping of the Starlock rings is determined

SAFETY ASSURANCE LEVEL

In accordance with the customer's guidelines and adaptation to the recommendations of the PN-EN ISO 12100 standard, the machine is equipped with a number of technical safety measures, such as: emergency switch, light curtain, safety switch, guards.

Benefits for the customer / user

- very good precision of clamping and repeatability of the process, thanks to the use of high-quality electric presses - moving accuracy ± 0.01 mm.

- control of the correctness of the clamping of the Starlock ring thanks to the cooperation of presses and a force sensor;

- detailed view of the process status from the operator panel;

- increasing production efficiency;

- easy service access for maintenance personnel - service door at the back of the machine;

- ergonomic design.