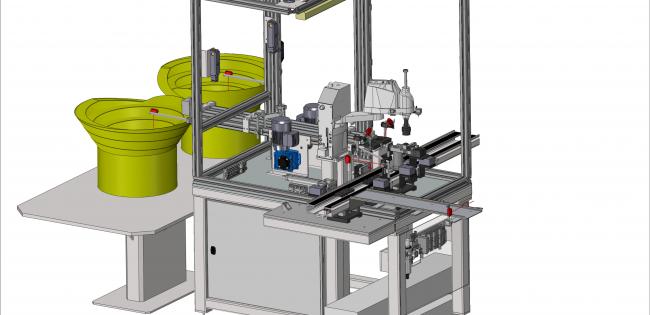

Robotised gasket assembly and inspection stand

A stand for the automatic assembly of two types of gaskets. The gaskets are attached to the starter casing, which moves on a small pallet on a belt conveyor.

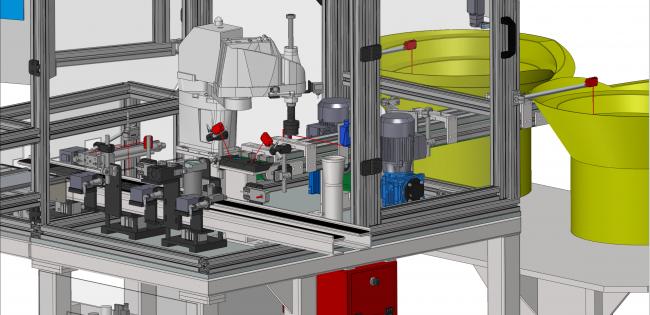

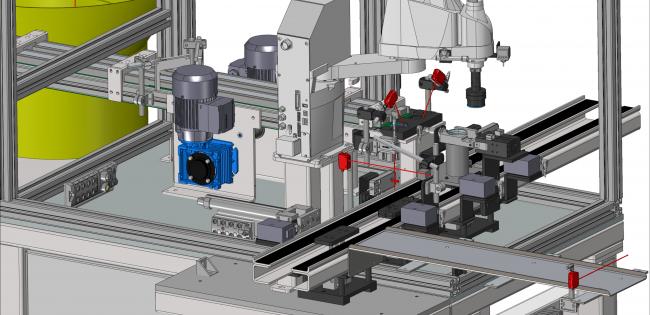

Each of the gaskets has its own vibratory feeder and belt feeder transporting it to the collection seat.

The collection seats are equipped with colour sensors that check the correctness of gasket type.

The heart of the machine is a SCARA robot that takes a gasket from one of the seats and puts it inside the starter housing. Thanks to the use of an Epson robot, a cycle time of 3.5 seconds was achieved. An additional element of the station is a control stand equipped with a video sensor and laser height measurement.

This provides the required control for 100% of manufactured parts. The worpieces classified as defective are pushed to the stand of defective parts, so that the main conveyor is not blocked and the continuity of manufacturing is maintained.